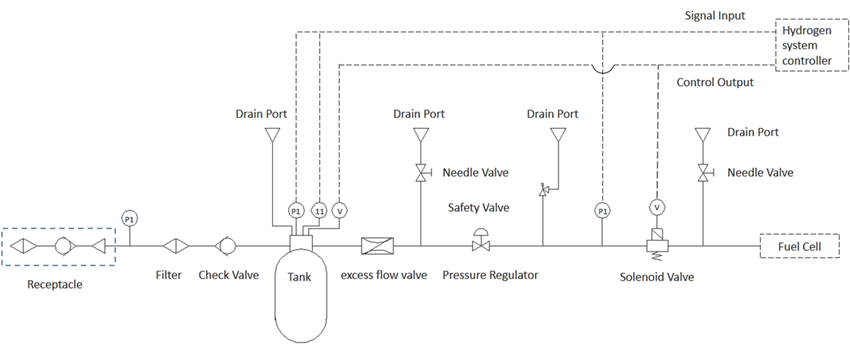

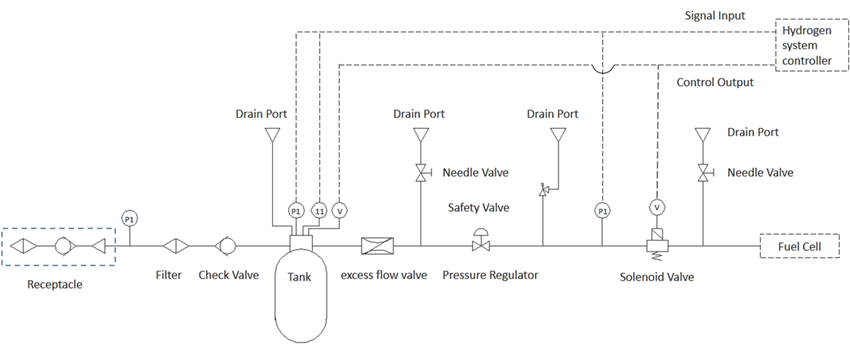

Hydrogen energy vehicles generally have 35MPa and 70MPa two kinds of pressure, hydrogen fuel cell vehicle hydrogen supply system can be divided into two parts, one part of the vehicle high-pressure hydrogen supply system; the other - part of the low-pressure hydrogen supply part, generally integrated in the fuel cell engine. Hydrogen system includes hydrogen refueling module, cliff pressure regulating module (combination valve), hydrogen storage module

Hydrogen storage module: contains high-pressure composite cylinders, cylinders and connecting piping, etc., each bottle is configured with a bottle valve, the end of the bottle is configured with a TRD (Thermal Relief Dissolution), and the cylinders are connected in parallel through the piping.

Hydrogenation Module: It contains a hydrogen filling port and a high pressure pressure gauge. The hydrogen filling port is integrated with a hydrogen filling nozzle, a filter, a check valve and other functional components. The hydrogen refueling module can also be integrated with a high-pressure venting valve according to user requirements, which is used to replace the gas in the cylinder and to discharge the high-pressure hydrogen in the cylinder actively during vehicle repair and maintenance.

Pressure regulating module (combination valve): Highly integrated and powerful, it simplifies the hydrogen system significantly. The combination valve contains a filter, a pressure reducing valve, a low pressure relief valve, an exhaust shut-off valve, a pressure sensor (optional) and other functional components. The low-pressure relief valve is used to relieve overpressurized hydrogen through the low-pressure exhaust line in the event of an overpressurization of the outlet pressure due to a lockout failure of the pressure reducing valve. Discharge shut-off valve is used for gas replacement, hydrogen system repair, maintenance, active discharge of hydrogen in the pipeline downstream of the bottle valve.

Key components:On tank valve (combination valve, generally integrated (TPRD), manual shut-off valve, solenoid valve, excess flow valve, pressure sensor, temperature sensor and other functional components), cylinder solenoid valve, shut-off valve, safety valve, pressure sensor, temperature sensor, hydrogen port, filter, check valve, overflow excess flow valve, pressure regulator reducing valve, solenoid valve, piping and so on.

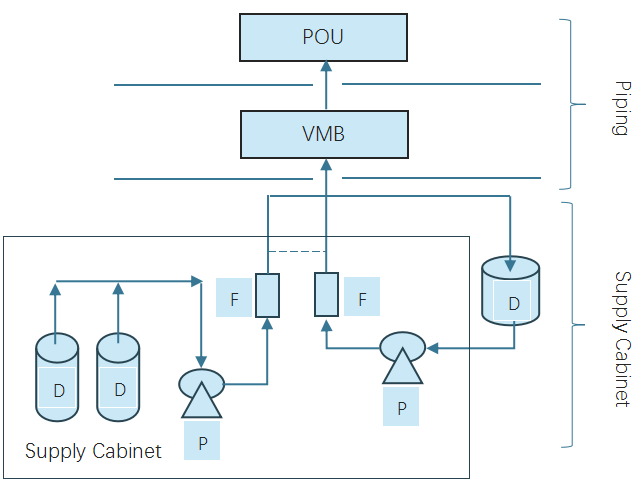

SMARTWE provides total solution for piping system of hydrogen fuel cell vehicle, with professional experience and knowledge in fluid control, excellent engineer team, fast service capability, professional product testing, we provide customers with high quality and reliable products and services, and at the same time, meet the customer's requirements for cost control.

Hydrogen Fuel Cell Vehicle On-board High Pressure Hydrogen Supply Piping System Diagram

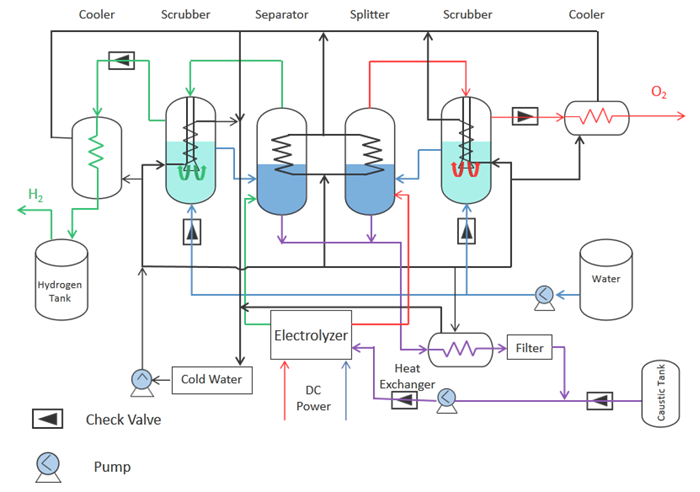

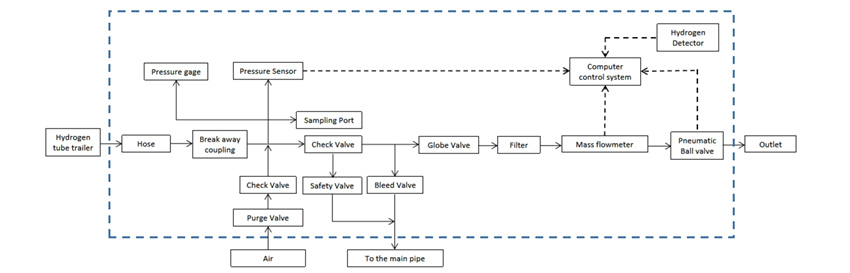

Hydrogenation station unloading column typical process system

Hydrogenation station unloading column typical process system